Meeting the demand of monitoring precise fill level in containers, Libelium has integrated a new sensor into its IoT platform. This device is compatible with

Smart Agriculture and

Smart Water solutions.

The new

radar level sensor “Vegapuls C21” uses 80 GHz radar technology which makes it highly effective compared to other sensors using technology such as ultrasound. In fact, the radar sensor measurement remains unaffected by temperature fluctuations, vacuum or high pressures and is also invulnerable to pollution.

Radar Level sensor VEGAPULS C21

Main VegaPuls C21 sensor features

- Operation frequency: 80 GHz

- Maximum detection distance: 15 m

- Accuracy: ±2 mm

- Operating temperature: -40 to 80 °C

Application examples

- Water tank measurement

- Bulk solids tank measurement

- Pumping stations

- Rain overflow basins

- Flow measurement in open channels

- River level control

- Early flood detection

- Sea tide monitoring

- Open containers

In certain sectors, knowing the precise fill level of a container can be crucial.

Libelium has verified the performance of the new Vegapuls C21 sensor in two installations: a grain silo in a pig farm and an aquarium water tank.

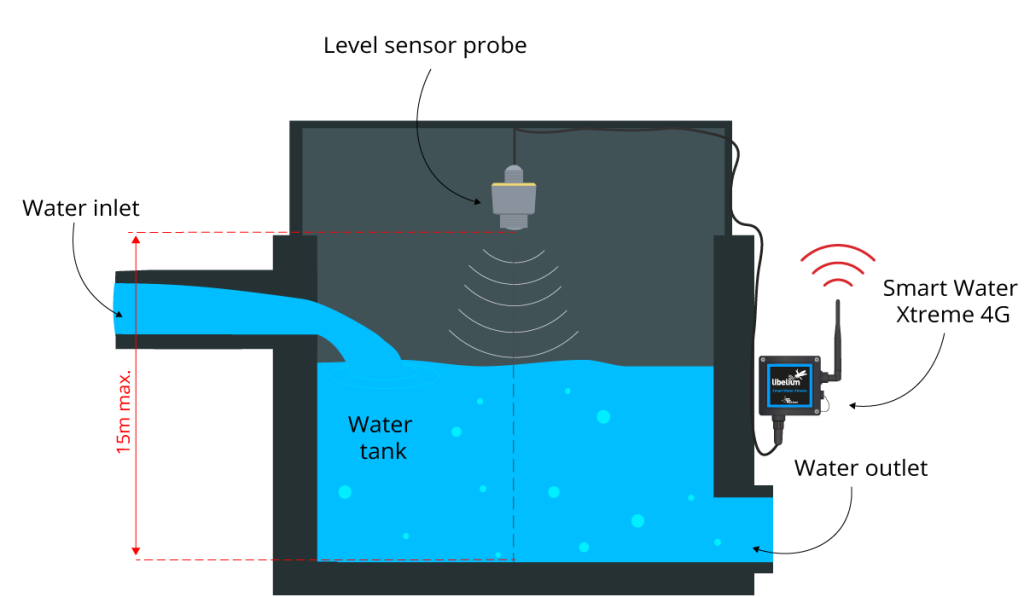

Liquid level control in a water tank

In the

Aquarium of Zaragoza (Spain) the measurement of the water tanks filling has been done manually with a stick and writing down on a paper. Since

the water is in constant motion, the staff were searching a way to modernize, digitize and, above all, make this measurement more accurate.

Radar level sensor installed in the aquarium tank

The Zaragoza Aquarium is the largest fluvial aquarium in Europe. Its fish tanks reflect the enormous biodiversity that lives in the rivers and exhibit species from Nile (Africa), Mekong (Asia), Amazon (America), Murray-Darling (Oceania) and Ebro (Europe). The loss of an animal means losing a little piece of our planet. Libelium has always collaborated closely with the Aquarium of Zaragoza staff developing IoT solutions for the control of the fish conservation conditions. For example, an Ambient Condition node was installed in the past in the Anaconda terrarium, and several Libelium’s sensors are measuring the water quality in the piranhas’ tank.

At the back of the aquarium,

the water management uses a drainage system. The water enters through a pipe to a general tank and leaves it through another direct conduit to the fish tanks.

If the water dropped to the level of the outlet duct it could cause air pockets. These would stick to the fish scales as small bubbles that would prevent them from breathing normally and could cause death by suffocation.

Diagram Vegapuls C21 sensor installation in the aquarium tank

Libelium

engineers integrated a Vegapuls C21 sensor in a Plug & Sense! Smart Water Xtreme and installed it into one of the tanks that provides water to the Amazonian fish tanks. A screen integrated into the node allows checking the of water level without any other device connected. Also sends the data every 15 minutes. Since the tanks are located underground, the use of a combination of LoRaWAN and 4G cellular protocols was necessary to send the data to the Internet.

The aquarium maintenance staff can see the filling level directly on the device’s display and also monitor the data via an Internet visualization app.

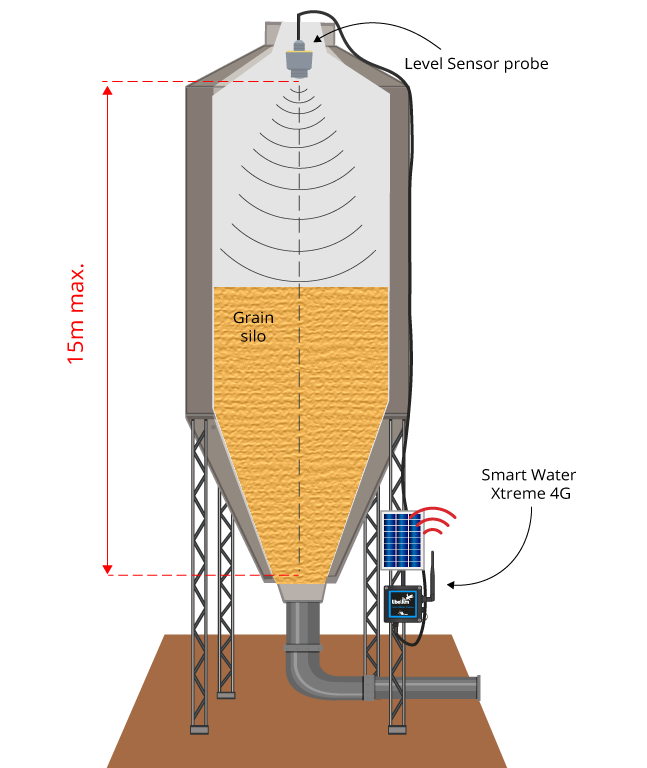

Solid level control in a grain silo

The versatility of this new radar level sensor allows the application in other kinds of containers, like grain silos. A pig farm in Huesca, Spain required the installation of the

Vegapuls sensor in the feed silos to know the animal’s grain fill level.

Libelium customer Serprovit develops and implements technological systems for livestock farms through the “PigData” project, a comprehensive data management platform on the fattening farm, which enables two-way communication throughout the integration system.

Diagram Vegapuls C21 sensor installation in a grain silo

In order to know the state of the silo, they installed the Libelium technology. On the farm, the deployment was complicated due to the height of the silo. The Vegapuls sensor requires a maximum of 15 meters in height to work properly. Using a crane, a technician placed the sensor in the silo, hung from the top.

The sensor is connected to a Plug & Sense! Smart Agriculture Xtreme node that sends the data via 4G to a server with a graphic visualization. Every 30 minutes the sensor sends the data to a server. In addition, a solar panel feeds the battery of the device. Setting an alert would let farmers know if the silo needs to be filled before getting empty.

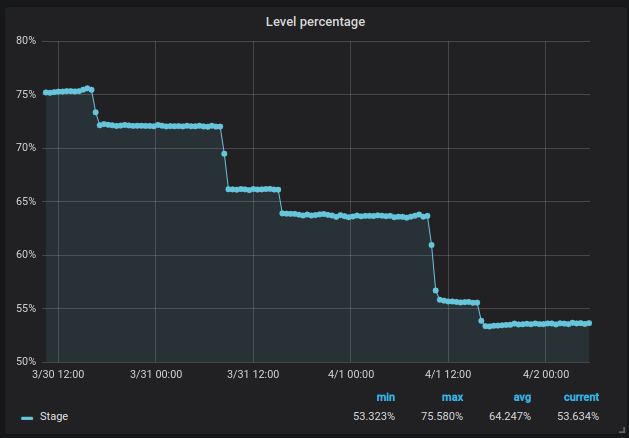

Graphic shows the grain level in a silo

The Internet of Things can be implemented on animal farms in many ways. A recent case study showed

how milk production on a farm could be increased by measuring certain parameters. The idea behind all these developments is to improve the living conditions of farm animals to increase both the quantity and the quality of the final product (meat, milk, eggs…). In this sense, investment in IoT technology can provide livestock companies with a competitive advantage.

Vega has a wide range of level measurement sensors that can be integrated with Libelium technology. Consult our

sales team to install them in your project.

FAQs

The Vegapuls C21 sensor has Ex approval for explosive atmospheres, but in which ones it does and in which ones it doesn’t?

Technologically there is no limitation of operation for radar technology in flammable areas (whether gas zone 0 or dust zone 20). On the other hand, please note that today only instruments with 4.20mA/HART electronics have the certifications for explosive areas. Instruments with Modbus electronics have the certification process pending (for zone 1 Gas or zone 21 Dust) in the “encapsulation” version.

Moreover, instruments with SDI12 electronics are not intended to be certified for Ex areas.

Is there a problem with measurements on powders, powdery things (flour, perlite, etc.)?

No, airborne dust is not a problem for the measurement, radar technology is practically inherent in this situation. The robustness of the measurement in applications with granular solids, such as liquids, depends largely on factors such as internal elements near the radar beam, proximity to the product inlet beam, the low dielectric constant of some products to be measured and large measuring ranges, e.g. perlite.

Does the accuracy change when the water sheet to be measured is moving? Are there installation recommendations in these cases?

Since the radar performs several measurement procedures during one second, the transmitted measurement value is an average of the different product heights that occur during stirring. The measurement value is a fairly reliable representation of what the liquid column would be without the stirring.

On the other hand, in some applications is interesting to measure even how the level changes during, for example, a strong surge. What makes a sensor capable of showing an “average” or more fluctuating value is the application settings.

The sensor must be configured according to whether you want to measure solids or liquids, but what if the sensor is not configured correctly, for example, the sensor is configured for liquids but is finally used for bulk solids? Would it give accurate measurements, and how would you know the difference?

In most applications, there is no effect on the measurement if a sensor is configured to measure granular solids and is instead mounted in a liquid application. Measured products with a high dielectric constant, such as a feed silo without internal obstacles, are “easy” applications. Where care has to be taken is in applications where the mounting recommendations are not respected (e.g. product inlet glued to the sensor), very low dielectric constant and a very large measuring range, etc., is where the settings of the application parameters have to be adapted to the reality of where the sensor is installed.

By default, how is the Vegapuls C21 sensor programmed? Does it always come for a water tank?

The default settings are for a water storage tank.

Nevertheless, the application parameter settings can be changed from the factory and on request for one or more sensors:

- The different “references” or configurations can be saved in your customer portal for future application replications or configurations (another thing we can discuss in the training).

- The configurations can be changed once supplied, as you know, through Bluetooth and also with the TeamViewer QuickSupport application, our technicians can connect to the sensors either in your facilities or at the customer’s house to modify configurations or to monitor the operation of the same and thus apply changes to the configuration, this support is free of charge is made at your request or the end customer.

- With the new firmware version of the instruments, the Modbus devices are expected to allow changes in some of the application parameters through your device.

Is there any need to calibrate the sensor over time due to measurement drifts?

No, all radar technology instruments are exempt from recalibration or fine-tuning.

How much does the sensor weigh?

The sensor weighs between 300 and 400 grams.

What happens if the sensor gets wet?

The sensor comes in an IP68 certified PVDF housing so if it gets wet or even submerged it will not be affected and will be able to take measurements again once it is out of water.

What are the advantages over ultrasound?

While ultrasonic sensors need to have a controlled ambient temperature and atmospheric conditions for proper operation, the radar is not affected by them. Ultrasound is not suitable for moving water surfaces. It is a small variation, about 5 centimeters, but in some applications, it can be crucial.

What is the maximum height it can measure?

Range of 15m with an accuracy of ±2mm.

If the sensor is placed in an inaccessible location but needs to be adjusted, how can this be done?

The Vega sensor can be adjusted remotely by the user.

At what frequency does the radar work?

It works with 80GHz which allows us to have more precision and minimize the angle of emission of the wave, making the measurement much more accurate. This radar has an angle of 8°, compared to other radars that work at 26GHz and give 30° of angle.